The Construction of Space Shuttle Launch Complex 39-B

What was all that stuff?

What did it do? What was it made of? How was it made?

And why did it need to be made that way?

A very personal-and-technical, written-and-photographic, thoroughly-researched history.

by

James MacLaren.

Part 2: Ivey Steel

Page 50: A Return to the Pad

| Pad B Stories - Table of Contents |

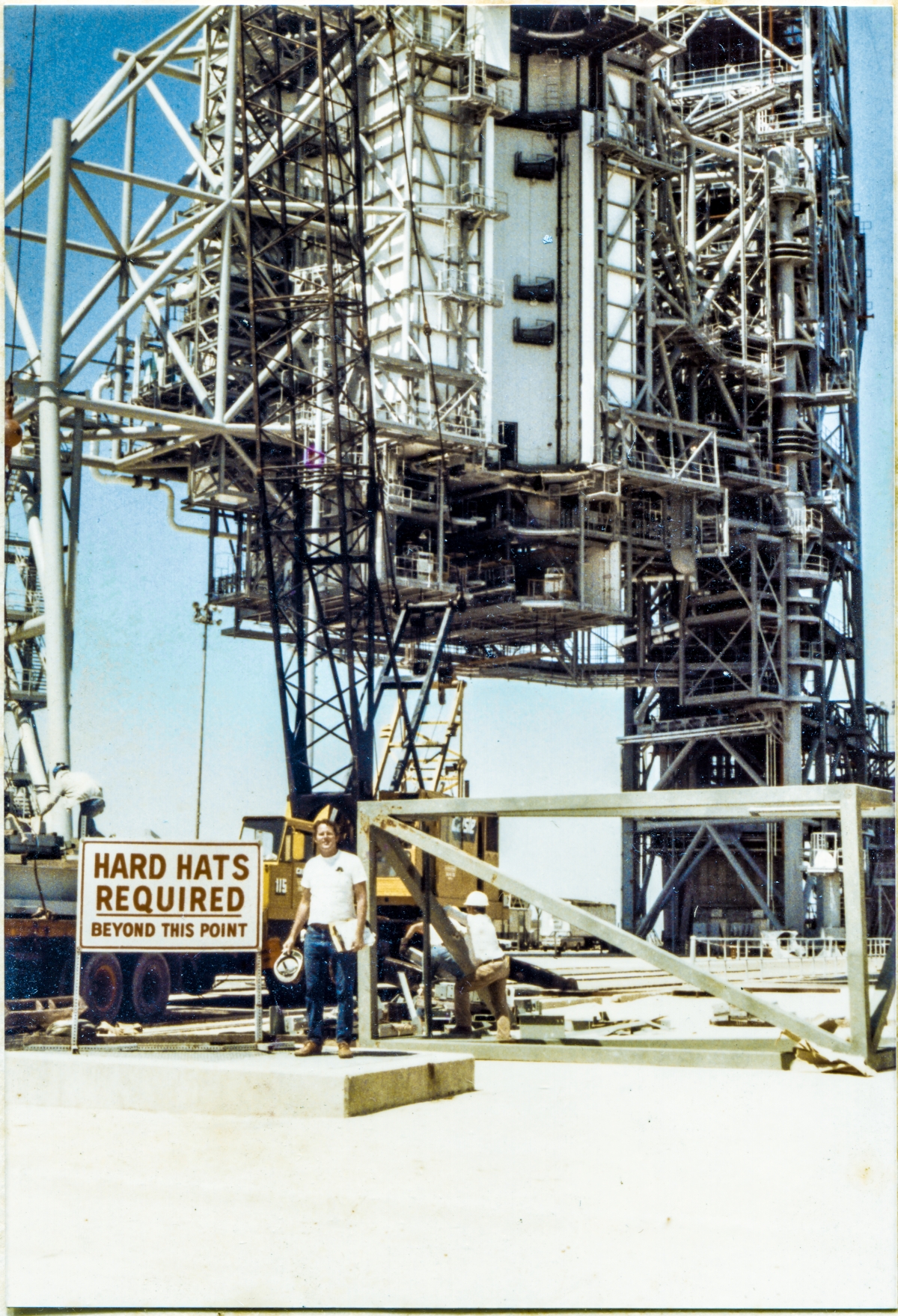

You are looking at Pad B at the beginning of my second period of time there, now working for Ivey Steel, following the close of my initial work experience at the Pad with Sheffield Steel. That's me, hardhat in hand, but alas I do not recall who held my camera and took this picture. It is a loss, and I fear I shall never recover it. Sigh.

Between those two periods of time, I was laid off, did not set foot on the Cape, and endured much at The Hand of Fate, including the loss of my home and the dissolution of my marriage.

Dick Walls no longer worked for Sheffield Steel, had found himself a job as Project Manager with Ivey's Steel Erectors, put Ivey's bid for this phase of work at the Pad together, and got the job as low bidder for the structural steel erection portion of the work.

And shortly after that, I got a phone call from him, asking me if I might want to go back to work, out at Pad B, once again.

And The Fates picked me right back up off the ground where they had so recently tossed me, and returned me to the exact place from which they had so unceremoniously snatched me, less than a year previously.

Apparently I had done well enough the first time, and when asked to return, I was no longer going to be an answering machine. I was now to be given day-to-day responsibilities as an integral part of the construction management of a very large steel erection job. Imagine that!

I marvel at the twists and turns, sometimes.

Whereas before, I was employed by a steel fabricator, I was now employed by a steel erector, and I thanked my lucky stars for every last thing I learned previously from the sterling crew of Wilhoit, for whom I did not even work at the time, but who yet somehow saw something in me, took me under their wing, and set about teaching me, whatever they could.

How can a thing like that even be?

I do not know.

Fate.

While I was away from the Pad, among many other things, both towers were sandblasted and repainted from bottom to top, and after that, the FSS was no longer red. Pearl Gray was the new color, and KSC-STD-C-0001 was the paint spec to which everything was now coated, and it would become a source of unnecessarily endless annoyance, trouble, groundless and pointless expense, and palpable physical danger, for us, and others, for the full duration of my time spent working for Ivey Steel at Pad B, late into 1985.

Ivey Steel was subcontracted under Sauer Mechanical, who was the prime contractor for the job, and Reynolds Smith & Hills no longer provided engineering oversight, and instead, both BRPH (Briel Rhame Poynter & Houser), and PRC (Planning Research Corporation) worked together on the engineering side of the house, and both were located in the combined field trailers which had been joined together at the far end of the field trailer parking lot at the Pad, with their intervening walls removed, forming a big open area where everybody's desk could be found. For the most part, the BRPH desks were in the north side of things, and the PRC desks were on the south.

We were all working NASA contract NAS10-10805. LC39B-FPC-4. With a drawing package that was titled "Launch Complex LC39B Shuttle Piping, Cabling and Equipment Installation." Drawing number 79K24048. The towers were "complete" but there was an awful lot more that needed to be done, structurally, mechanically, and electrically, before they would be fully finished and ready to support operational Space Shuttle launches.

And let us now pick things back up more or less right where we left off, and continue with our journey of understanding, learning how Pad B was built, and why it was built the way it was.

And we step back just a bit, to review.

And perhaps we can do a comparison, using similar photographs.

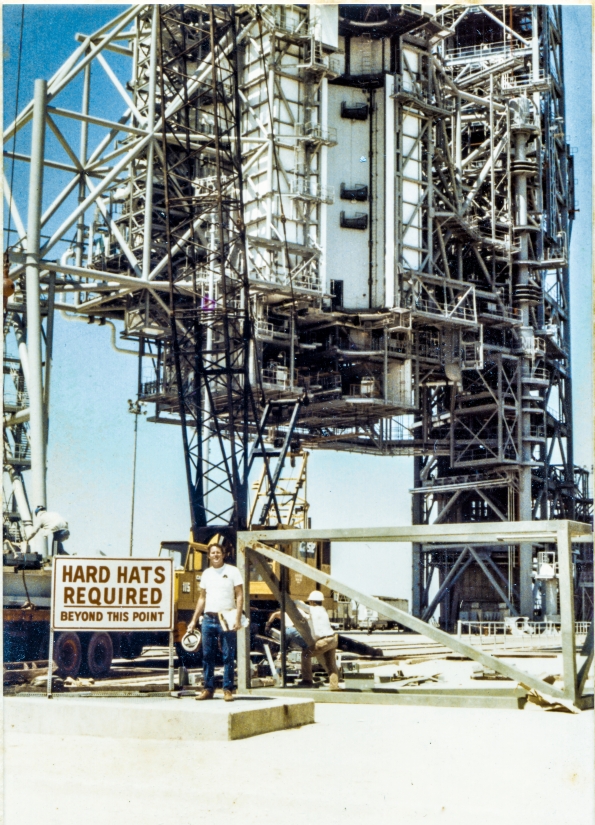

Left, our last photograph from this angle showing the towers with a red FSS, and right, our photograph above, showing a gray FSS.

And when you enlarge both images, and give things a good close looking-over, you can see that they are very nearly identical.

Significant similarities on the RSS are to be found in the area of the Orbiter Mold Line in the 135'-7" floor steel and below, the ends of the PBK & Contingency Platforms that face the Orbiter on either side of the centerline of the RSS and PCR at Column Line 4, the well-exposed white insulated-metal paneling which covers the face of the RSS/PCR between Column Lines 3 and 5, and the area extending downward from the RCS Room at its side margins along Column Lines 3.4 and 4.6.

These and other areas are where much was done when I was working for Ivey Steel.

Above and beyond the "Weathershield" (which was there to protect personnel and equipment, and not the orbiter) at the personnel door to the Antenna Access Platform, there is no Orbiter Weather Protection System, of any kind, in any place.

No Centaur Platform, no Centaur Porch.

And there are no Swing Arms hanging off the face of the FSS, nor is there an OMBUU hanging off the face of the RSS. None of that which interfaces directly with the Orbiter, through direct physical contact, has come to be, and we will be seeing all of that and more appear on the towers as we journey through Part 2 of these photo essays.

Actual changes between our two photographs are minute.

In the older photograph, the Canister Access Platform is flipped down, but in the newer image it has been retracted up into its raised position. The RSS Side 4 curved monorail piece above the PBK & Contingency Platforms looks to be temporarily tied off in an intermediate position between full raised and fully lowered, and in the newer photograph it's all the way up, locked and stowed. And maybe a very few other items too.

The towers I had left were the exact same towers I returned to.

We will rejoin our journey of learning about the Pad by asking, "What is it that I'm standing on? What's that odd bit of raised concrete there, where I'm sharing space with a sign that reads "Hard Hats Required Beyond This point."

And it's called the Engine Service Kart Power & Communications Pit, and it's electrical, and here it is, located for you on a 79K24048 Site Plan.

It was originally constructed along with all the rest of the Pad back during the Apollo Program, and as you can see here, it was part of an extensive network of electrical installations which spiderwebbed beneath the surface across the full expanse of the Pad and beyond.

And we can look at its location a little closer on one of the Apollo structural drawings, and then after that we can see how it was actually built.

And since we've come this far, let's go on and look at it in a little more detail on one of the Apollo electrical sheets, and on this one we can see that there's a 30 KVA transformer in there, and that's enough power to give something a pretty good kick, so our Pit turns out to be a Real Place, that handles Real Work.

Just behind me, and to the right, with the truck driver who delivered the load of iron that's being offloaded by Ivey's Union Ironworkers from Local 808 lounging against it, the cut-off top of the East Stair Tower lays on its side, ready to be hauled off to the KSC recycling facility and landfill at Ransom Road.

In the distance, up in the air on the RSS, the exterior portion of the Localized Payload A/C System is partially visible (shown in a very rough-cut and incomplete way, including a couple of places where some of it is visible through Stair Tower 4), and we haven't talked about it yet, and we're never going to be getting a good image of it, so we may as well talk about it now, using what we have, while we've got the chance to.

This was a thing which furnished very nice air that the end-users, the people who owned and operated the Payloads, needed, and it had to be set up in a way that different Payloads, oftentimes with very different configurations and needs, could all be accommodated, so it kind of went all over the place, and it was many things for many people.

Here's the schematic for it, and over on the right, inside the large box which represents the Payload Changeout Room, there's a vertical line labeled "Interface", and on the left side of that line it's labeled "Hard Duct", and on the right side it's labeled "Flex Duct By User", so the right side of that line is where all of the peculiarities and customizations required by peculiar and custom payloads would start, and it was the responsibility of the payload's owner to ensure that the very nice air was supplied to their payload in whatever peculiar and custom way that payload demanded.

Outside of the PCR, it was this great snarl of ducting, boxes, and the platforming and framing which held it all up and held it all together, and here's a look at that, right here.

And since I know how much you like this stuff, here's some more of it, just because.

During this time, at the beginning of the 79K24048 Work Effort, I found myself thrown together with a random and disparate team of other people, many of whom I never, or very nearly never, crossed paths with, some of whom I found myself interacting with on a regular-enough basis but not particuraly often or closely, and a few of whom I found myself interacting with all the time, closely, and with whom I had to find a way to fit in socially, and do so well, if I wanted things to work smoothly.

Just like before, working 79K14110. Just like anywhere else.

And some were Good, and some were middle of the road, and some were Not So Good, also just like before, and just like anywhere else, and it was the Good Ones that I wound up bonding with, for the duration of the job, and as before in Part 1, it will be those people you'll be hearing about the most here in Part 2.

Over at the other end of the parking lot, over on the west end of things where the BRPH/PRC Engineering people were located, somebody at some point decided it would be kind of cool to have dedicated stickers for the job made up, and strictly on their own, that's exactly what they did.

Stickers are ubiquitous in a place like this, and it's a rare hardhat indeed that isn't customized and personalized in some way with stickers on it.

People do this sort of thing, all the time. I myself one time had 50 t-shirts made up, emblazoned with a large Titan IV logo on the back, and another smaller one on the front pocket, which wound up being worn by many people who worked at Complex 41 during the late 1980's, but that's a story to be told, and a book to be written, another day, and another time, and certainly not right now.

Hardhat Stickers are a whole unique little world in and of itself, and I wish that, at the time, I had the presence of mind to do an entire photographic set of nothing but people's hardhats, with all the utterly unique customizations to be found on them in the form of stickers, but alas, I did not.

Ephemeral things.

They're here...

...and then they're gone.

Irretrievably.

Forever.

And a person we're going to be hearing about a lot in Part 2, Jack Petty, at some point very early on asked me if I wanted a sticker that somebody had cooked up over at the BRPH/PRC end of things, and I took one look at the thing, and said, "Hell yes!" and he gave me two of them, and one was instantly on my hardhat, front and center, and the other one wound up in my photo albums, and here you go, here it is...

This little sticker that you're seeing here has somehow passed through The Eye of the Needle, and survived long enough for your own eyes to behold it, as a direct result of it's being defective.

Somehow, when the print job was run, this particular piece of adhesive-backed plastic sheet entered the cutting portion of the machine that did the work... offset.

It wasn't centered.

But apparently the mismatch wasn't quite enough to cause the machine to either recenter it or reject it, and it came through the process as you see it here, with the image well off to the side.

Which is why it wound up in my photo album.

The good one, the one that was centered, wound up on my hardhat, which, after enough years went by, cracked, fell apart, and was relegated to the trash along with its sticker which of course was lost forever, then and there.

And I marvel sometimes, how things work.

How The Hand of Fate picks and chooses.

How it sets things up.

How it leans strongly first this way, and then suddenly turns things around, taking life, and giving life, to things, and people, you would never imagine would end up passing, and failing, as they ultimately wind up doing so.

There can be no reason for it.

There can be no accounting for it.

But everything is in its thrall.

It is inescapable.

It is a Deep Thing.

A thing Beyond Knowing.

How.....?

Why.....?

And no answer is ever given.

In the photograph up at the top of this page, the Beehive Sticker is not visible on the hardhat hanging from my right hand.

But it's there.

Return to 16streets.comACRONYMS LOOK-UP PAGEContact Email Link |